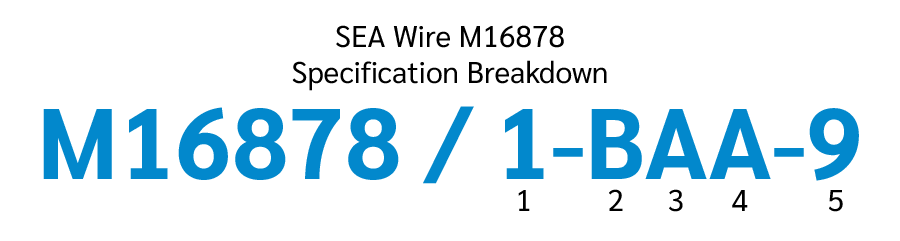

(M16878) – General Information

- M16878/20 Type ET (Wrapped)

- M16878/21 Type E (Wrapped)

- M16878/22 Type EE (Wrapped)

- M16878/23 Type ET (Extruded)

- M16878/24 Type ET (Wrapped)

- M16878/25 Type E (Extruded)

- M16878/26 Type E (Wrapped)

- M16878/27 Type EE (Extruded)

- M16878/28 Type EE (Wrapped)

- M16878/29 Type F

- M16878/30 Type FF

- M16878/32

- M16878/34 Type EE (Wrapped)

- M16878/35 Type EE (Wrapped)

- M16878/38

Table 1

| Current Spec | Previous Spec | Jacket | AWG | Conductor Coating |

|---|---|---|---|---|

| /1 | B | PVC | 32-14 | Tin |

| /2 | C | PVC | 26-12 | Tin |

| /3 | D | PVC | 24-0 | Tin |

| /4 | E | TFE | 30-10 | Silver |

| /5 | EE | TFE | 26-12 | Silver |

| /6 | ET | TFE | 30-20 | Silver |

| /11 | K | FEP | 24-10 | Silver |

| /12 | KK | FEP | 24-10 | Silver |

| /13 | KT | FEP | 24-20 | Silver |

| /21 | E | TFE - W | 22-12 | Silver |

| /22 | EE | TFE - W | 12-4 | Silver |

| /23 | ET | TFE | 30-20 | Nickel |

| /25 | E | TFE | 22-12 | Nickel |

| /26 | E | TFE - W | 22-12 | Nickel |

| /27 | EE | TFE | 26-12 | Nickel |

| /28 | EE | TFE - W | 12-4 | Nickel |

| /34 | EE | TFE - W | 12-4 | Silver |

| /35 | EE | TFE - W | 12-4 | Nickel |

Table 2

| Letter | Description |

|---|---|

| A | Bare copper |

| B | Coated copper |

| C | Coated copper clad steel |

| D | Coated high strength copper alloy |

| E | Coated copper with overall metallic coating |

Table 3

| AWG | Letter |

|---|---|

| 32 | A |

| 30 | B |

| 28 | C |

| 26 | D |

| 24 | E |

| 22 | F |

| 20 | G |

| 18 | H |

| 16 | J |

| 14 | K |

| 12 | L |

| 10 | M |

| 8 | N |

| 6 | P |

| 4 | R |

| 2 | S |

| 1 | T |

| 0 | U |

| 00 | W |

| 000 | Y |

| 0000 | Z |

Table 4

| Number of Strands | Letter |

|---|---|

| 1 | A |

| 7 | B |

| 10 | C |

| 16 | D |

| 19 | E |

| 26 | F |

| 37 | G |

| 41 | H |

| 65 | J |

| 105 | K |

| 133 | L |

| 168 | M |

| 259 | N |

| 665 | P |

| 817 | R |

| 1045 | S |

| 1330 | T |

| 1672 | V |

| 2109 | W |

Table 5

| Designator | Color |

|---|---|

| 0 | Black |

| 1 | Brown |

| 2 | Red |

| 3 | Orange |

| 4 | Yellow |

| 5 | Green |

| 6 | Blue |

| 7 | Violet |

| 8 | Gray |

| 9 | White |

Note 1

Nema Types:

- E (M16878/4)

- EE (M16878/5)

- ET (M16878/6)

Note 2

- X = Extruded

- W = Wrapped

Note 3

- B = Silver-coated Copper (SCC)

- C = Nickel-coated Copper (NCC)

- D = Silver-coated high-strength copper alloy (SCA)

- E = Nickel-coated high-strength copper alloy (NCA)

- F = Silver-coated copper clad steel (SCCCS)

- G = Nickel-coated copper clad steel (NCCCS)

Note 4

| AWG | Letter |

|---|---|

| 32 | A |

| 30 | B |

| 28 | C |

| 26 | D |

| 24 | E |

| 22 | F |

| 20 | G |

| 18 | H |

| 16 | J |

| 14 | K |

| 12 | L |

| 10 | M |

| 8 | N |

| 6 | P |

| 4 | R |

| 2 | S |

| 1 | T |

| 0 | U |

| 00 | W |

| 000 | Y |

| 0000 | Z |

Note 5

| Number of Strands | Letter |

|---|---|

| 1 | A |

| 7 | B |

| 19 | E |

| 37 | G |

| 133 | L |

| 665 | P |

| 817 | R |

| 1045 | S |

| 1330 | T |

| 1672 | V |

| 2109 | W |

Note 6

| Designator | Color |

|---|---|

| 0 | Black |

| 1 | Brown |

| 2 | Red |

| 3 | Orange |

| 4 | Yellow |

| 5 | Green |

| 6 | Blue |

| 7 | Violet |

| 8 | Gray |

| 9 | White |