Supply Chain Connectivity Solutions

Global Connectivity & Services

SEA Wire and Cable offers a portfolio of services designed for global connectivity and consistent supply across complex networks:

- Worldwide inventory access: Stock visibility and allocation models to support multi-site programs and international deliveries.

- Custom inventory programs: Kanban, vendor-managed inventory (VMI), and consignment models tailored to program cadence and forecasting accuracy.

- Regulatory & compliance support: Documentation support for export controls, customs, and aerospace certifications to keep shipments moving and audit-ready.

- Technical application engineering: Cable spec translation, application guidance, and pre-shipment verification to ensure the right product arrives on time.

These services enable customers to consolidate vendors and reduce administrative overhead while improving responsiveness for both planned production and urgent retrofit requirements. With the use of these services, SEA positions itself as a trusted partner for organizations requiring high-performance wire and cable solutions.

EDI Solutions for Streamlined Transactions

SEA Wire and Cable’s EDI platform provides immediate benefits by dramatically reducing transaction time, increasing order accuracy, and integrating seamlessly with major aerospace and defense industry systems where precision is non-negotiable, thus making it the BEST CHOICE! This ensures that customers experience faster order cycles, fewer manual corrections, and a direct reduction in administrative workload. Electronic Data Interchange (EDI) is fundamental to modern supplier-customer collaboration. SEA’s EDI implementation focuses on reliability, standards compliance, and integration simplicity:

- Core EDI transactions supported: Purchase orders, order acknowledgments, advance ship notices, invoices, and inventory reports.

- System compatibility: Configurable maps that integrate with ERP systems to minimize manual intervention and data-entry errors.

- Turnkey onboarding: SEA provides implementation support, test plans, and phased rollouts to reduce integration risk and business interruption.

- Data integrity & auditability: EDI logs and archival support help supply chain teams meet audit and contractual reporting requirements.

Implementing EDI reduces lead-time variability, removes manual transcription errors, and accelerates cash-to-cash cycles for both buyers and SEA.

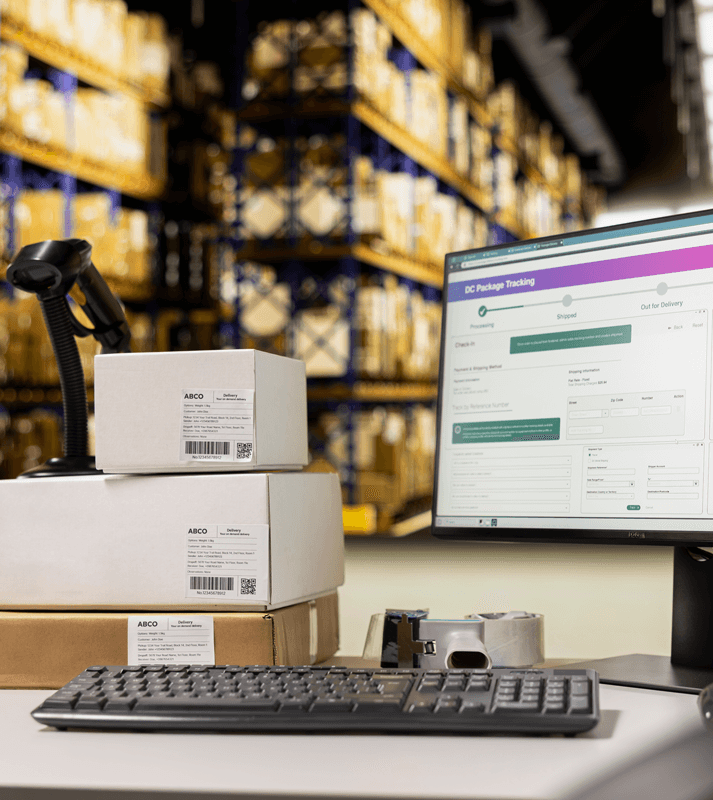

Improving Warehouse Efficiency with Barcoding

SEA Wire and Cable employs advanced barcoding technologies within its expansive warehouse operations to make sure of rapid product turnover for high-priority military and aerospace clients. These capabilities help organizations avoid costly delays, maintain complete control over their inventory, and significantly reduce input errors that would otherwise disrupt mission-critical timelines. Barcoding and automated identification are foundational to modern warehouse efficiency, helping companies avoid costly delays and streamline warehouse management. SEA’s warehouse operations use barcode-driven processes for receiving, inventory control, kitting, and shipping:

- Unique item-level barcodes: Support lot-level and serial-level traceability required by aerospace and defense programs.

- Cycle counting & reconciliation: Barcode-driven cycle counts reduce reconciliation time and improve inventory accuracy.

- Kitting and assembly workflows: Barcode scanning assures kits are assembled to spec, reducing rework and non-conformance.

- Integration with warehouse management systems (WMS): Real-time inventory updates feed EDI transmissions and customer portals.

These practices reduce picking errors, accelerate throughput, and make audit trails simple to produce during inspections, ensuring quick product turnover for high-priority military clients.

Real-Time Tracking for Seamless Cable Shipments

Real-time tracking allows businesses to avoid delivery delays and operational disruptions by providing full visibility into cable shipments while in transit. SEA Wire and Cable’s tracking solutions make sure that high-value cable orders arrive on time, protecting production schedules and supporting predictable project execution. Visibility into shipment status is crucial when cable deliveries are on the critical path. SEA’s real-time tracking capabilities include:

- Shipment event monitoring: Automated status feeds from carriers with exceptions flagged for proactive resolution.

- Customer portal access: Single-pane-of-glass dashboards where customers can view shipment location, estimated delivery, and supporting documents (e.g., packing lists, certifications).

- Exception management: SEA’s logistics team triages delays, customs holds, and other issues to minimize program impact.

Real-time tracking reduces the time procurement and production teams spend chasing status and improves the predictability of downstream activities. With SEA’s commitment to the military and aerospace industries, its tracking solutions help avoid potential delays caused by logistics issues, assuring high-value cable orders are delivered on time.

Integrated Shipping Solutions with UPS & FedEx

SEA Wire and Cable’s seamless shipping integrations with UPS and FedEx optimize delivery speed and reliability. These integrations help large clients—such as major aerospace firms like Boeing—receive shipments faster, improving customer satisfaction and supporting the stringent timelines and accuracy expected in aerospace and defense supply chains. Fast, reliable delivery often depends on strong carrier relationships. SEA maintains integrated shipping solutions with major carriers to balance speed, cost, and traceability:

- Carrier-negotiated rates & service levels: Access to commercial and expedited services that meet high-priority delivery needs.

- Automated carrier booking: Shipments are booked and labeled through integrated systems, reducing label errors and manual booking delays.

- Cross-border expertise: Documentation management for international shipments and coordinated customs brokerage to minimize hold times.

- Proof of delivery & returns handling: Electronic PODs and streamlined RMA processes help close the loop on deliveries and returns quickly.

These integrations make it straightforward to select the right balance of speed and cost while maintaining strong visibility into each shipment. Sea’s integration with major carriers helps clients receive shipments faster, improving customer satisfaction.

Why Choose SEA for Scalable, Compliant Connectivity Solutions

SEA Wire and Cable’s scalability and AS9100-certified compliance make it an ideal partner for aerospace, defense, and other highly regulated industries that require dependable, audit-ready supply chain solutions. SEA’s robust infrastructure, process discipline, and ability to scale with customer demand ensures that even the most complex programs maintain continuity and compliance, driving trust and reliability. SEA Wire and Cable brings several competitive advantages for organizations seeking scalable, compliant supply chain partners:

- Industry-savvy compliance: Processes built to support AS9100-level traceability and documentation where required by customers.

- Flexible fulfillment models: From single-line orders to continuous VMI and Kanban programs, SEA’s fulfillment strategies scale with program needs.

- Technical and logistical expertise: Integrated engineering and logistics teams that bridge product knowledge with delivery execution. SEA provides a “Cable Wizard” (a tool that acts as an interactive cable selection and specification assistant) to help engineers design cables that are both spec-compliant and readily available, reducing lead times and procurement risk.

- Risk reduction and continuity: Inventory planning, multi-channel sourcing, and carrier redundancies help protect programs from single-point failures.

Together, these elements allow customers to reduce working capital tied up in inventory, avoid program delays, and meet the strict documentation and traceability expectations of regulated industries. SEA’s certified systems allow businesses to grow their operations without compromising on compliance or quality.

Contacting SEA Wire and Cable for Tailored Solutions

SEA Wire and Cable encourages engagement for personalized supply chain connectivity solutions that directly address customer pain points. Their expertise and capabilities offer superior service to the wire and cable industry, guaranteeing that clients benefit from tailored strategies, streamlined operations, and high-performance delivery models. To collaborate with SEA for tailored supply chain connectivity solutions, procurement teams typically follow a short intake and scoping process:

- Initial contact & requirements capture: Provide program specs, expected volumes, forecast cadence, and any regulatory constraints.

- Solution design: SEA’s application engineering and supply chain teams propose a solution—whether it’s EDI onboarding, a VMI program, or expedited shipping lanes.

- Pilot & transition: A phased pilot reduces risk and validates integration points (EDI mappings, WMS interfaces, shipping labels).

- Scale & continuous improvement: Post-implementation reviews and KPIs (on-time delivery, inventory accuracy, transaction cycle time) drive iterative improvements. For immediate inquiries or to request a formal capability brief, contact SEA Wire and Cable’s supply chain team via their corporate contact channels (www.sea-wire.com) and request a tailored connectivity assessment.

Partner With SEA Wire & Cable

SEA Wire and Cable stands as a strategic force multiplier for organizations seeking to build fast, resilient, and compliant supply chains. Through integrated EDI capabilities, advanced barcoding systems, robust warehouse operations, real-time tracking, and optimized UPS/FedEx carrier connections, SEA delivers a fully modernized supply chain ecosystem built for aerospace, defense, and other high-stakes industries. With AS9100-certified processes and the scalability required to support both rapid-response missions and long-term program sustainment, SEA Wire and Cable assures customers receive unmatched accuracy, speed, and reliability across every stage of the procurement lifecycle. These capabilities directly mitigate supply chain risk, eliminate costly delays, and strengthen operational readiness for industries where precision and timeliness are non-negotiable. Organizations looking to streamline operations, elevate fulfillment performance, and secure a compliant, future-ready supply chain are invited to partner with SEA WIRE and CABLE. With tailored connectivity solutions and a commitment to customer success, SEA provides the expertise, infrastructure, and reliability needed to keep programs on schedule and mission-ready.