Optimizing Services & Inventory Management

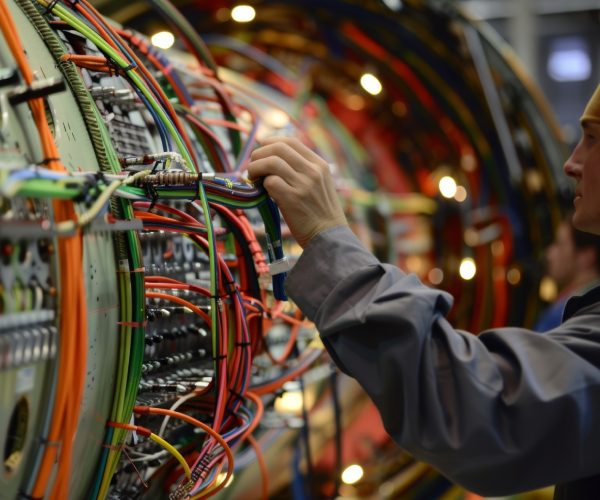

In aerospace, defense, and advanced manufacturing sectors, uninterrupted production depends on precise, reliable inventory control. Cable assemblies and high-performance interconnects form the foundation of mission-critical systems where delays or material shortages can halt operations or compromise readiness. SEA Wire and Cable has engineered a comprehensive suite of service and inventory management capabilities designed to eliminate these risks and enhance operational reliability.

Through State-of-the-Art Just-In-Time (JIT) methodologies, Kanban (visual signal) replenishment systems, custom inventory solutions, and a robust national distribution infrastructure, SEA Wire and Cable enables customers to reduce the risk of running out of critical materials while eliminating excessive stock levels. These capabilities empower aerospace and military programs to achieve consistent, predictable, and highly efficient cable supply chains.

SEA Wire and Cable’s Role in Modern Service & Inventory Management

SEA Wire and Cable enhances supply chain performance by integrating advanced logistics strategies with deep cable engineering expertise. A trusted partner for companies needing fast, reliable cable inventory management solutions SEA Wire and Cable is your go-to distributor for top-quality, AS9100 certified materials. Their service model includes demand forecasting, stocking programs, real-time tracking, and responsive customer support to ensure uninterrupted access to mission-critical wire, cable, and interconnect components. SEA Wire and Cable has over 15,000 items in stock and 80 million feet of wire ready for shipment.

By simplifying procurement cycles and reducing administrative burdens, SEA Wire and Cable delivers a more agile, efficient, and dependable materials pipeline tailored to the requirements of aerospace and military operations.

Solving Cable Inventory Challenges with SEA Wire & Cable

Aerospace and defense programs often grapple with fluctuating demand cycles, long supplier lead times, and high costs associated with carrying excess inventory. SEA Wire and Cable addresses these challenges through programs designed to stabilize material flow, eliminate over-purchasing, and ensure that essential components are always available when needed by using JIT material management solutions.

SEA works closely with engineering, procurement, and production teams to align material availability with actual program consumption, enabling total readiness without tying up capital or risking shortages plus reducing unnecessary costs while meeting project deadlines.

Custom Cable Inventory Solutions to Fit Your Needs

Every mission-critical program has unique operational, technical, and logistical requirements. SEA Wire and Cable meets these needs by offering Custom Cable Inventory Solutions built around each customer’s workflow, production cadence, and risk profile.

These solutions may include:

- Customized stocking levels based on burn rates

- Tailored packaging, labeling, and batch-tracking

- Dedicated shelf space for specialized or proprietary cables

- Support for multi-site replenishment and distributed production

- Scalable inventory agreements that adapt to production changes

This individualized approach ensures that every customer receives an inventory program engineered precisely for their environment, performance expectations, and mission objectives.

Just-In-Time Management Tailored to Your Business

SEA Wire and Cable’s JIT systems synchronize material delivery with the customer’s exact production flow. Instead of a generic supply model, SEA Wire and Cable conducts detailed usage and schedule analysis to design a material supply rhythm that reduces storage/excess stock and cost burdens, improves throughput, and increases operational predictability.

These JIT capabilities allow organizations to achieve Just-In-Time cable supply for aerospace and military projects, where timing precision is essential to mission success. SEA Wire and Cable’s experience with industry leaders like Boeing, Lockheed Martin, and Unison Industries guarantees understanding the precise needs of all projects.

Kanban Inventory Systems to Keep Your Projects Moving

SEA Wire and Cable’s Kanban solutions provide automated replenishment that ensures the continuous availability of critical materials. These systems:

- Trigger restocking as inventory is consumed

- Maintain minimum levels to prevent shortages

- Reduce manual oversight

- Support lean, high-efficiency manufacturing

Kanban programs create a steady, uninterrupted material flow — ideal for long-term aerospace and defense production ensuring zero downtime for your operations.

Get Efficient Cable Management Now with SEA Wire & Cable’s Just-In-Time Solutions

SEA Wire and Cable’s JIT programs deliver immediate improvements to operational efficiency, reducing procurement complexity and providing predictable access to critical cable products. These solutions ensure consistent availability without unnecessary stockpiling, strengthening both cost control and production stability. Whether managing multiple projects or navigating complex supply chain requirements, SEA Wire and Cable offers real-time automated inventory tracking, automated stock replenishment, and flexible delivery schedules. With SEA’s AS9100 certified processes, inventory is stocked to meet all required strict standards.

Why Choose SEA Wire and Cable for Your Cable Inventory Management

SEA Wire & Cable stands out as a trusted partner for aerospace and defense supply chains because of its proven ability to combine reliability, customization, and technical excellence in every aspect of cable inventory management. Organizations choose SEA Wire and Cable because:

- Industry-Leading Reliability: SEA Wire and Cable has a long-standing reputation for delivering products on time, according to specification, and with complete documentation and traceability.

- Aerospace & Military Expertise: SEA Wire and Cable understands the mission-critical nature of defense and aviation programs and designs its inventory solutions to align with these demanding environments.

- Comprehensive Quality Assurance: Every stocked and shipped product is backed by rigorous testing—from Hi-Pot and spark testing to pull and dimensional verification.

- Customization at Every Level: SEA Wire and Cable’s ability to tailor JIT programs, Kanban systems, and specialized inventory solutions ensures that customers receive exactly what their program requires.

- Expansive On-Hand Inventory: With one of the most extensive cable inventories in the industry, SEA Wire and Cable supports fast turnaround, reduced lead times, and immediate readiness.

- Dedicated Support and Technical Guidance: SEA Wire and Cable partners closely with procurement, engineering, and operations teams to refine forecasts, reduce waste, and sustain long-term program stability.

Together, these strengths make SEA Wire & Cable a strategic advantage for organizations

that require precision, continuity, and uncompromised quality in their cable supply chains.

Modern Facility & Expansive Stock to Support Rapid Delivery

SEA Wire and Cable’s advanced stocking facility maintains a wide-ranging inventory of aerospace-qualified, military-grade, and specialty cables. This infrastructure ensures rapid response, short lead times, and reliable product availability for both routine and urgent program needs (80,000 square foot facility holds 80 million feet of wire with over 700 types stocked).

Customers benefit from:

- A large, diverse inventory

- Unmatched product traceability

- Fast order processing

- Reliable fulfillment under demanding timelines

Ensuring Quality and Performance through Rigorous Testing

Quality assurance is integral to SEA Wire and Cable’s inventory management framework. SEA incorporates a full suite of testing methods into its distribution operations, ensuring that every product meets the stringent performance standards expected in aerospace and defense environments.

A full suite of testing methods is incorporated into SEA Wire and Cable’s distribution processes, affirming that every product meets the stringent performance standards expected in aerospace and defense environments.

These include:

- Hi-Pot testing for dielectric strength

- Spark testing for insulation integrity

- Pull testing for mechanical strength

- Dimensional and electrical verification for spec accuracy

Being AS9100 certified SEA Wire and Cable is committed to delivering exceptional service that reduces costs, improves quality, and guarantees timely material availability.

SEA Wire and Cable assures that every shipped product is fully validated and ready for mission-critical use.

Partner With SEA Wire & Cable

SEA Wire & Cable delivers a comprehensive and high-performance approach to cable inventory management for aerospace, defense, and advanced manufacturing organizations. Through customized inventory solutions, JIT and Kanban systems, extensive on-hand stock, and rigorous quality testing, SEA Wire and Cable provides a supply chain framework that is lean, reliable, and tailored to mission-specific needs.

By choosing SEA Wire & Cable as a partner, organizations gain a trusted source of high-quality cable products delivered with precision, consistency, and full adherence to the demanding requirements of military and aerospace applications with 50+ years of consistent service to these industries.

Do not wait for inventory problems to affect your projects — contact SEA Wire and Cable to see how your cable supply chain can be transformed!