Services & Cable Engineering Testing

Introduction

High-reliability cable systems form the backbone of today’s most advanced aerospace, military, and industrial platforms. As technology evolves and system complexity increases, the need for precise, comprehensive cable engineering testing has never been greater. Every wire and cable must deliver consistent electrical performance, withstand mechanical and environmental stresses, and meet strict compliance standards to ensure mission success and operational safety.

This whitepaper examines the role of cable engineering testing across defense and aerospace applications. It highlights key testing methodologies—such as Hi-Pot, pull testing, and spark detection—while demonstrating how SEA Wire and Cable’s extensive inventory, advanced facility, and AS9100-certified processes enable rapid, dependable testing and product delivery. Together, these capabilities support the highest levels of quality, reduce costs and waste, and help customers meet demanding program requirements with confidence.

What is Cable Engineering Testing?

Cable engineering testing is the structured evaluation of wire, cable, and harness assemblies to verify their electrical, mechanical, and environmental performance. These tests ensure that conductors, insulation, shielding, and terminations comply with specification requirements and remain functional throughout the product’s lifecycle.

For defense, aerospace, and high-reliability commercial sectors, testing validates that cables can endure intense vibration, extreme temperatures, voltage surges, and exposure to fluids or chemicals. It identifies potential issues early, ensuring system readiness and reliability.

SEA Wire and Cable enhances this process with extensive in-stock inventory and rapid-turn service. Because the cable/wire is already in stock, testing and quality control can be done proactively. Their large selection of military- and aerospace-grade wire allows testing workflows to begin immediately, reducing procurement delays and enabling fast deployment of high-quality, fully tested cable solutions.

Why Electrical Cable Quality Testing is Critical

Electrical cable quality testing is vital to ensure consistent system performance and prevent catastrophic failures. Even small defects—such as insulation thinning or improper crimps—can lead to electrical instability, signal loss, or safety hazards. Because cables are often installed in inaccessible areas, undetected issues can result in expensive repairs, rework, or operational downtime.

Testing enables early detection of defects, ensures compliance with stringent industry and military standards, and confirms that cables can operate safely under demanding conditions.

SEA Wire and Cable’s testing processes directly support its goal of reducing costs and waste while improving overall product quality. By catching issues early and validating performance at every stage, SEA Wire and Cable reduces scrap, minimizes re- manufacture, and delivers highly reliable products that lower total lifecycle cost. Cost reduction, waste reduction, and quality improvement is achieved at the same time by tightly integrating engineering, supply-chain discipline, and advanced testing procedures.

SEA Wire and Cable applies rigorous testing upfront using advanced electrical, mechanical, and environmental testing to catch any issues at the earliest stages. High quality reduces waste, both in material and labor, while also reducing cost from defects.

In the end:

- Quality drives efficiency,

- Efficiency reduces waste,

- Waste reduction lowers cost.

Engineering Testing for Military and Aerospace Wires

Military and aerospace environments present extreme conditions that demand the highest degree of cable reliability. Engineering testing for these wires includes evaluating conductor resistance, insulation integrity, shield continuity, tensile strength, flammability characteristics, and environmental durability.

Tests simulate real-world scenarios such as temperature cycling, chemical exposure, vibration, and altitude changes. This ensures cables comply with MIL-DTL, AS, and OEM requirements and can perform across the full operational profile of aircraft, spacecraft, ground vehicles, missiles, and naval systems.

SEA Wire and Cable’s AS9100-certified quality management system ensures adherence to stringent industry standards. This certification provides structured control over every

process—from material sourcing to testing and documentation—ensuring product safety, traceability, and consistent high performance.

AS9100 Certification provides:

- Strict Control of Material and Traceability

- Rigorous Risk Management and Hazard Prevention

- Advanced Documented Processes for Testing and Inspection

- Control of Non-Conforming Products

- Calibration and Equipment Accuracy

- Supplier Quality Management

- Employee Competency and Certification Requirements

- Continued Process Improvements

Understanding Hi-Pot Testing for Cable Insulation

High Potential (Hi-Pot) testing verifies insulation strength by applying voltages far above normal operating levels. This method reveals pinholes, micro-cracks, contamination, or spacing issues that could lead to arcing or electrical failure.

Given the harsh conditions encountered in aerospace and military systems—such as high- altitude environments, surges, vibration, and humidity—insulation integrity is mission- critical.

SEA Wire and Cable ensures every cable meets high safety standards by incorporating rigorous Hi-Pot testing into its quality workflow. Essential for aerospace and military applications, Hi-Pot testing is one of the most critical steps in certifying cable safety.

These controlled, precise evaluations confirm that insulation will perform reliably under stress, supporting safe and consistent operation in demanding applications.

The Importance of Pull Testing for Cables

Pull testing confirms the mechanical strength of crimps, terminations, and conductor connections. By measuring the force required to separate components, this test ensures that terminations can endure vibration, shock, and mechanical load throughout the cable’s lifetime.

Mechanical integrity is essential for reliable electrical connection—especially in high- impact environments such as aircraft, armored vehicles, and naval equipment.

SEA Wire and Cable demonstrates its commitment to delivering dependable products through stringent pull-testing procedures. Each test is performed to exceed industry and

MIL-SPEC requirements, making sure cables maintain structural integrity under the toughest conditions. The use of regularly calibrated tensile testers designed for wire, cable, and crimp validation reinforces the integrity of testing results. Test results are recorded for full traceability. This data becomes part of the product’s permanent quality record.

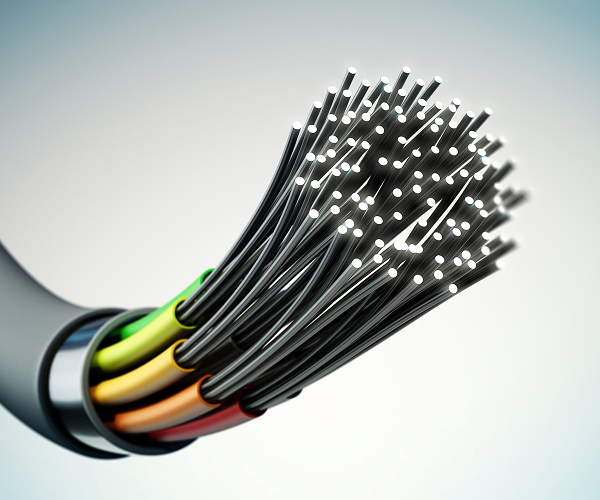

Wire Spark Testing for Early Detection of Faults

Spark testing rapidly detects insulation defects by passing the cable through a high-voltage field that identifies pinholes, thin spots, or inconsistencies. This early screening prevents flawed cable from advancing into assembly or field use.

Catching insulation issues early avoids costly rework, reduces waste, and increases product reliability.

SEA Wire and Cable leverages advanced spark-testing capabilities and expert technicians to identify potential issues long before they become costly problems in mission critical environments. Their sophisticated equipment and proactive methods ensure only defect- free materials move forward into customer applications. According to required standards (MIL-SPEC, aerospace, UL), all validation is documented creating traceability evidence.

When Spark Testing is paired with AS9100 controls, calibrated equipment, and documented inspection procedures, it becomes a powerful tool to guarantee safe, high- intensity, mission-ready cable performance.

SEA Wire and Cable’s Approach to Comprehensive Cable Quality Control

SEA Wire and Cable employs a full-spectrum quality control program that includes electrical, mechanical, dimensional, and environmental testing. Their structured processes verify compliance with MIL-SPEC, AS, and OEM requirements while ensuring complete traceability and performance validation.

Tests include continuity checks, insulation resistance evaluations, tensile measurements, environmental conditioning, and material verification executed within a controlled, precision-driven workflow.

SEA Wire and Cable’s modern facility (80,000 sq ft) and expansive in-stock inventory (over 80 million feet of wire and more than 15,000 product lines) enable quick turnaround on both testing and product delivery. With advanced laboratories, automated inspection tools, and a large supply of ready-to-test materials, SEA-Wire and Cable can initiate testing immediately, supporting urgent program deadlines without compromising accuracy or quality.

SEA Wire and Cable has become a trusted partner for aerospace, defense, and commercial clients.

Why SEA Wire and Cable is the Best Choice for Cable Engineering Testing

Selecting a cable testing partner influences system reliability, compliance assurance, and overall mission success. SEA Wire and Cable’s advanced capabilities, seasoned engineering staff, and rigorous processes enable comprehensive evaluation of cables used in high-risk, high-performance environments.

From electrical performance validation to mechanical durability testing and environmental simulation, SEA Wire and Cable offers complete testing coverage executed to the strictest standards.

SEA Wire and Cable’s ability to meet the most demanding military and aerospace requirements sets them apart. Their AS9100-certified system, advanced facility, broad inventory, and proven expertise ensure that every cable is engineered, tested, and delivered to meet the highest levels of performance and reliability.

There are five core strengths on which SEA Wire and Cable’s capabilities are built on:

- AS9100 Certified Quality Management Systems

- Expertise in High-Spec and MIL-Spec and Aerospace Materials

- Advanced testing Capabilities Required by Defense and Aerospace Engineering

- In-House Engineering and Certified Technicians

- Rapid Response Through a Modern Facility and Expansive Inventory

Conclusion

Cable engineering testing is a critical component of ensuring the safety, reliability, and functionality of electrical systems used in aerospace, defense, and other high-reliability industries. Techniques such as Hi-Pot, pull testing, and spark detection provide essential insight into cable performance, enabling early detection of defects and verification of compliance with stringent standards.

SEA Wire and Cable delivers unmatched value through its extensive in-stock inventory, AS9100-certified processes, modern facility, and comprehensive testing capabilities. By prioritizing quality, reducing waste, and supporting rapid turnaround, SEA Wire and Cable empowers customers to meet the most demanding technical requirements with confidence. Their commitment to excellence makes them a trusted partner for mission- critical cable solutions across the military, aerospace, and industrial sectors.