Custom Cable Services

Custom-Built Cables for Mission-Critical Performance and Reliability

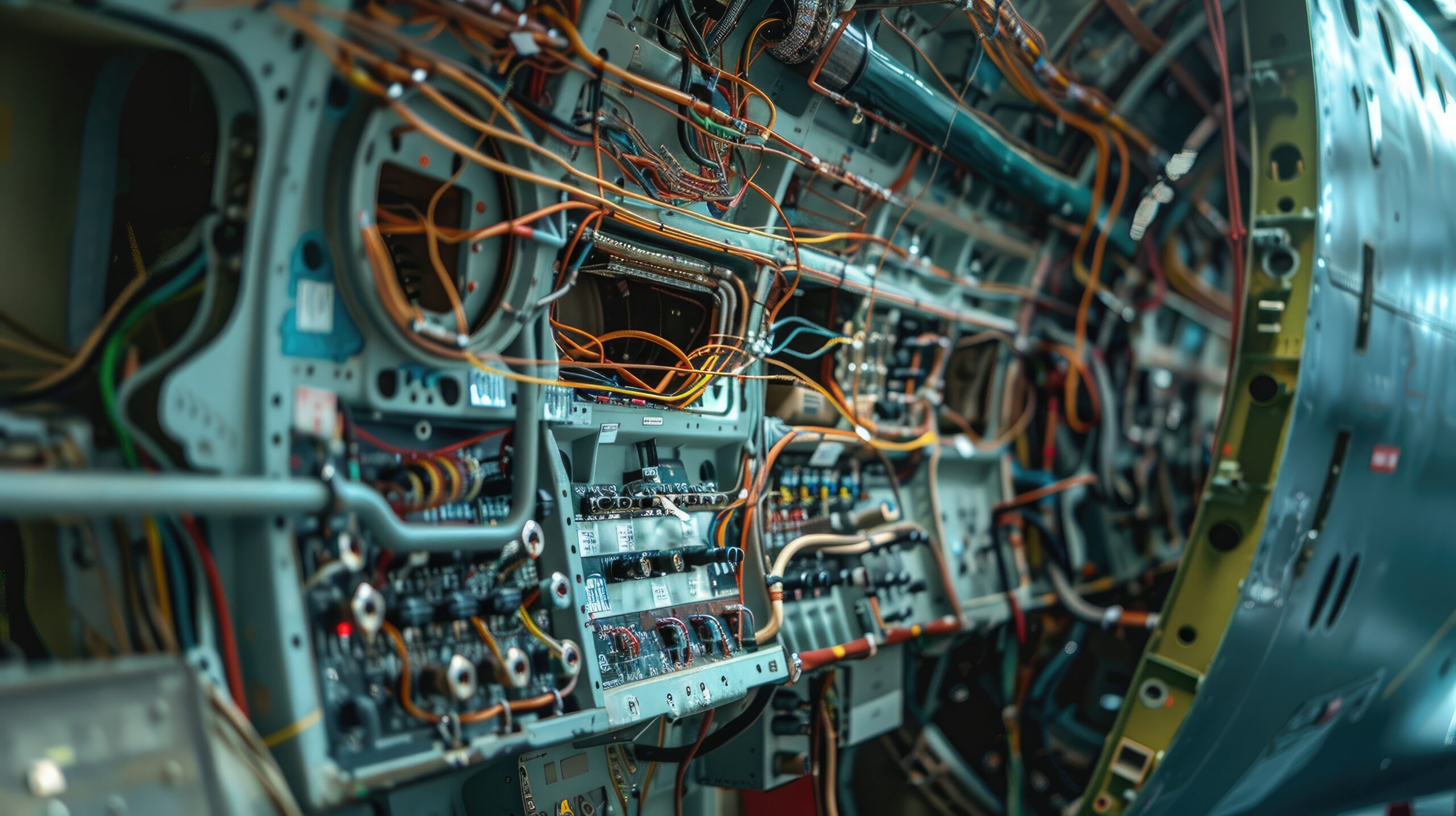

Mil-Spec Custom Cable Solutions

Custom products require reliability, performance, and precision that are non-negotiable as they are often designed to perform multiple functions at once. Whether it’s an aircraft, satellite, military vehicle, automation system, or a condition monitoring sensor every system relies on intricate wiring solutions to function seamlessly. When standardized, off-the-shelf cables fall short of meeting the demanding specifications of these industries, custom cables become the critical solution. SEA Wire and Cable offers unparalleled technical expertise tailored with a customer-centric approach that makes us the preferred choice for custom cable design support to meet the most exacting requirements.

Tailored Solutions for Complex Needs

Interconnect systems often operate in extreme environments—exposed to temperature fluctuations, electromagnetic and radio frequency interference (EMI/RFI), mechanical stresses, chemical contact, and more. These challenging conditions demand cables that not only meet strict industry standards but are also customized to fit unique design and application requirements.

At SEA Wire and Cable, we understand that a one-size-fits-all approach doesn’t work for these applications. Our team collaborates closely with clients to develop solutions that match their precise needs. Whether it’s a prototype, hard-to-find components, mixed media composites, an application-specific design, or an upgrade to an existing system, we tailor each solution to ensure optimal performance in the most cost-effective way.

Expertise in Compliance and Standards

Many product applications are governed by a rigorous set of specifications and standards that ensure safety, reliability, and interoperability. SEA Wire and Cable has decades of experience working with these complex requirements; we ensure that every custom cable we design meets or exceeds these stringent standards. Our custom cable solutions are not only crafted for performance but also comply with the highest industry standards, ensuring seamless integration into your systems with minimal risk of failure.

Robust Design Process for End-to-End Solutions

The process of developing application specific custom cable involves far more than just selecting materials and components. SEA Wire and Cable’s design process is thorough, addressing every aspect of cable performance from the choice of conductors and insulations to the termination of connectors, backshell, and ferrite beads during the assembly process. Our experts pay close attention to factors like:

- Environmental Conditions: Whether your cables will be exposed to extreme temperatures, chemicals, moisture, or high-pressure systems, we design cables that can withstand it all.

- Mechanical Stress: For applications involving dynamic movement, we consider the bending radius, flexibility, flex-life, and abrasion resistance of your cable to ensure it remains durable and effective.

- Electromagnetic Interference (EMI): Many aerospace and defense systems operate in EMI-sensitive environments. We offer shielding solutions that protect against interference, ensuring uninterrupted system operation.

This holistic approach guarantees that every custom cable we create is fit for purpose, offering the durability, flexibility, and reliability needed for mission-critical applications.

Speed, Precision, and Flexibility in Manufacturing

A key differentiator of SEA Wire and Cable is our ability to balance speed and precision. We understand that timing can be everything. Delays in cable production can have cascading effects on project timelines. Our state-of-the-art manufacturing partners, combined with our technical team, allow us to design and deliver custom cables quickly without compromising on quality.

Moreover, we offer flexible inventory solutions, including Long-Term Agreements, Consignment, and Vendor Managed Inventory (VMI), to ensure you always have the cables you need on hand. This helps mitigate long lead times, reduce stockouts, and prevent costly delays, so you can stay on schedule and within budget.

End-to-End Support, from Design to Aftermarket

Supporting custom cable needs doesn’t stop once the cables are delivered. SEA Wire and Cable offers comprehensive after-market support, ensuring that your cables perform throughout their lifespan. Our services include:

- Prototyping and Testing: Before full-scale production, we can prototype custom cables and subject them to rigorous testing to ensure they meet the required specifications.

- Future-proofing: We also consider long-term requirements during the design phase, incorporating service loops or designing cables to make field repairs and next generation upgrades easier.

This full-circle approach of our service ensures that your system and reputation remains reliable and well-supported throughout its lifecycle.

Exceptional Customer Collaboration

At SEA Wire and Cable, we believe that successful custom cable solutions begin with a collaborative partnership. We work closely with engineers, project managers, and procurement teams to fully understand your unique application and specific needs. By maintaining open communication throughout the design and manufacturing process, we ensure that the end result perfectly matches your expectations.

Our team is available at every step of the way—from the initial consultation and design phase to final production and beyond. We are here to guide you through every decision.

Focus on Innovation

Innovation is at the heart of everything we do at SEA Wire and Cable. We are constantly researching and implementing the latest technologies in cable materials, production methods, and testing procedures to deliver cutting-edge solutions that meet the evolving needs of our clients.

Whether it’s incorporating new lightweight materials for aerospace applications, improving cable shielding for EMI protection, or improving phase stability in high frequency coaxials, we ensure that our custom cables are at the forefront of industry advancements.

Custom Processing

SEA provides custom processing including, striping, twisting, cutting, printing, and marking. SEA uses laser marking to print a single string of up to 100 characters.

Striping

SEA can perform custom striping on 8 – 30 AWG wire including insulations like PVC, TFE, PTFE, cross-linked insulations like tefcel, and even nylon jacketed materials like THHN wire. We specialize in short runs with a 100ft minimum requirement. Watch the video here.

- Hi-temp

- Low-temp

Cut and Mark

With either Sumimark, Sumitag, or Cab printers, SEA can custom mark any identification label from Sumitomo, TE, or Brady. Let SEA be your outsource partner for all your cable needs. We use our Windows driven Sumimark, and Tagprint Pro 2.0 label creation software to produce advanced labeling solutions. Watch the video and read more here.

- SumiMark marking system

Twisting

To offer greater flexibility in the manufacturing process SEA also has the capability of twisting multi-conductor wires in-house. With our industry leading machines and equipment, we can twist wires from 8 to 30 AWG. With our custom planetary twister we can accommodate wire as large as 6 AWG. Watch the video and read more here.

- Regular Twist

- Planetary Twist

Cut and Strip

SEA offers a broad range of cut and strip options utilizing state of the art Komax equipment. To help streamline your manufacturing process, SEA has the capability of cutting your wire to its needed length. For no additional charge, we can also strip the insulation back and package with custom bar code. Watch the video and read more here.

- Approximate minimum cut length = 1/2″

- Approximate minimum strip length = 1/10″ (.10)

Laser Marking

Laser marking is a high quality, durable identification method for use with high-performance wire and cable used by the aerospace industry. SEA can provide custom marking on white or colored insulation including XLETFE, PTFE, FEP, ETFE or similar jackets, up to 6 AWG. Watch the video and read more here.

- Able to print a single string of characters 1-100 characters long.

- Able to print different messages on each end of the wire.

- Able to process cut material.

- Able to print Kapton, Tefzel (ETFE), Irradiated Tefzel (XLETFE), Teflon (PTFE or FEP), and other materials

Custom Aerospace Cables

SEA Wire and Cable supports designs for aerospace-grade cables that meet the most stringent standards. Our custom cables are engineered for high durability and reliability in extreme environments, from aircraft wiring to satellite systems.

Applications: Aircraft systems, UAVs, military aircraft, satellite communications.

Benefits: Lightweight, high-performance, and able to withstand temperature extremes and electromagnetic interference (EMI).

Custom Defense Cables

Our defense cables are built to handle the toughest conditions, including high-impact, vibration, and environmental stresses. Whether for military communication systems, radar, or tactical electronics, our custom cables are designed for unmatched reliability.

Applications: Military communication systems, tactical electronics, SATCOM, radar systems, power distribution systems.

Benefits: High shielding performance, flame-retardant, and flex-life for field use.

Custom Defense Cables

Our defense cables are built to handle the toughest conditions, including high-impact, vibration, and environmental stresses. Whether for military communication systems, radar, or tactical electronics, our custom cables are designed for unmatched reliability.

Applications: Military communication systems, tactical electronics, SATCOM, radar systems, power distribution systems.

Benefits: High shielding performance, flame-retardant, and flex-life for field use.

Custom Flexible Cables and Coil Cords

Our flexible cable and coil cords are designed for dynamic applications where movement is constant. Ideal for machinery, robotics, and communication systems these cables can be bent, twisted, and coiled without losing performance or durability.

Applications: Robotics, automated manufacturing systems, conveyors, tactical communication

Benefits: Extreme flexibility, high fatigue resistance, and long-lasting performance.

Custom Industrial Cables

SEA Wire and Cable manufactures custom industrial cables that meet the high standards of today’s manufacturing and automation environments. These cables are flexible, durable, and capable of withstanding extreme temperature variations and mechanical stress.

Applications: Manufacturing plants, robotics, control systems, heavy machinery.

Benefits: Resistant to wear and tear, chemical-resistant, and adaptable for dynamic applications.

Custom High-Temperature Industrial Cables

Our high-temperature cables are ideal for environments where heat resistance is paramount. These cables are designed to perform reliably in environments with constant exposure to elevated temperatures, such as found in power generation and industrial heating.

Applications: Power plants, industrial furnaces, oil rigs.

Benefits: Long-lasting performance in high-heat environments, abrasion-resistant, and versatile.

Custom Commercial Wiring Solutions

Whether for office buildings, industrial complexes, or commercial equipment, our custom wiring solutions are designed to meet the specific needs of your business. From low-voltage cabling to high-voltage power cables, we provide reliable and durable solutions.

Applications: Commercial buildings, data centers, security systems.

Benefits: High reliability, flexibility, and enhanced fire safety ratings.

Custom High-Frequency and Data Cables

For industries like telecommunications, networking, and satellite systems, SEA Wire and Cable offers custom high-frequency and data cables designed to transmit data at high speeds with minimal loss. Our cables are engineered to handle the demanding specifications of today’s high-bandwidth applications.

Applications: Telecommunications, data centers, broadcasting, radar systems.

Benefits: Superior signal transmission, low attenuation, and high bandwidth.

Custom Automotive and Commercial Cables

SEA Wire and Cable designs custom automotive cables tailored to meet the rigorous standards of the automotive industry. Our cables are engineered for high durability, flexibility, and excellent electrical performance to support powertrain, infotainment, and advanced driver-assistance systems (ADAS).

Applications: Electric vehicles (EVs), infotainment systems, powertrain wiring.

Benefits: Compact, lightweight, and designed for enhanced electrical performance.

Capabilities:

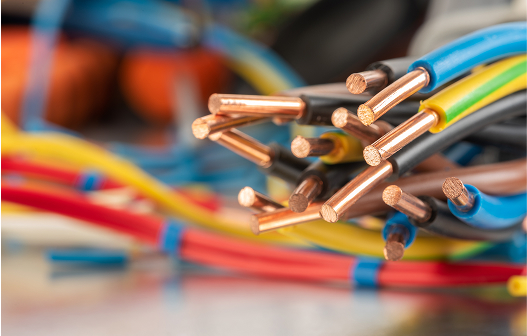

1) Conductors

Size Range: 1100 KCM – #50 AWG

- Bare Copper

- Tin, Nickel or Silver Plated Copper

- Grade “A” Nickel

- High-Strength Alloys

- High-Performance Conductors

- Thermocouple Alloys

- Carbon Fiber

- Tinsel

- Titanium-clad Copper

- Aluminum

- Precious Metals

2) Insulation Materials

- Polyethylene (PE)

- Cellular PE

- Polypropylene (PP)

- Various Polyurethanes

- Polyester Elastomer

- Hytrel ®

- Nylon

- Noryl ®

- TPE

- TPN

- TPR

- TPV

- Santoprene ®

- Fluoro Elastomer

- Viton ®

- mPPE

- mPPO

- XLPE

- XLPO

- PVC

- SR-PVC

- PVC Blends

- E-CTFE

- Halar ®

- Cellular Fluoropolymer

- MFA

- PVDF

- Kynar ®

- ETFE

- Tefzel ®

- Tefzel 750 ®

- XLETFE

- FEP Teflon ®

- PFA Teflon ®

- ECA3000®

- ECA4000®

- Various Silicone Rubbers

- Silicone Rubber Blends

- PTFE

- LDPTFE

- Tapewrap

- LSZH

Many of these available in Aerospace, Defense, Industrial, and Medical Grade

3) Tapes

- Mylar ®

- Polyester

- Ceramic

- Fiberglass

- Fluoropolymer (PTFE, ETFE)

- Water Blocking

- Various Metal Laminate

- pTFE

- Skive pTFE

- Low-Density (PTFE, PP)

- Heat-Sealable

- Mica

- Non-Woven Polyester

- Tissue Paper

- Nomex®

- Kapton®

4) Braid Materials

Textiles:

- K-Fiber

- Kevlar® Blend

- Kevlar®

- Ceramic

- Fiberglass

- Teflon Glass

Metals:

- Bare Copper

- Tin, Nickel and Silver-Plated Copper

- Grade “A” Nickel

- High-Strength Alloys

- Stainless Steel

- Metal Clad Fiber

- Precious Metals

- Specialty Materials

5) Jacketing Materials

- Polyethylene (PE)

- Cellular PE

- Polypropylene (PP)

- Various Polyurethanes

- Polyester Elastomer

- Hytrel ®

- Nylon

- Noryl ®

- TPE

- TPN

- TPR

- TPV

- Neoprene (extruded or blown)

- EPDM

- Santoprene ®

- Fluoro Elastomer

- Viton ®

- mPPE

- mPPO

- XLPE

- XLPO

- PVC

- E-CTFE

- Halar ®

- Cellular Fluoropolymer

- MFA

- PVDF

- Kynar ®

- ETFE

- Tefzel ®

- XLETFE

- Tefzel 750 ®

- FEP Teflon ®

- PFA Teflon ®

- ECA3000®

- ECA4000®

- Various Silicone Rubbers

- PTFE

- Tapewrap

- LSZH

Many of these available in Aerospace, Defense, Industrial, and Medical Grade

6) Additional Components

- Vent Tubes

- Fiber Optics

- Customer Supplied Materials

- Variety of Strength Members

- Solid Rods

- Water Blocking Fillers & Powders